The Evolution of Mobile Platform Traction Systems

September 12, 2018

The evolution of DC motor and gear motor technology has opened the doors to lightweight, battery-efficient solutions for mobile platform traction systems.

From medical mobility to industrial robotics and warehouse automation, mobile platform traction systems have become more affordable, manageable and efficient in large part due to the advancements of motors and integrated gearbox technology. These advancements reduce the size and weight of the motor and allow for design improvements such as direct drive of wheels, which eliminate components and reduce cost.

ElectroCraft Motion Control Solutions

ElectroCraft Inc. is a global provider of dependable, application-engineered, fractional-horsepower motor and motion products. ElectroCraft has contributed to the creation and propagation of mobile platform traction systems through innovations in brush and brushless DC motors and integrated gearmotor designs.

ElectroCraft motors exhibit many advanced innovations and features:

- Powerful and highly efficient, small-frame DC motors

- High starting torque, ideal for use in rough or uneven terrain

- Speed-torque characteristics that are optimized for wheel drive applications

- Highly responsive for quick acceleration

- Compact footprints

- Extremely durable and flexible gearbox designs

- Designed to provide efficient operation and long battery life

Advancing Technology for the World

ElectroCraft gear motors are highly reliable, cost-effective, industrial-strength products that have evolved and expanded over time to become ideal mobile platform traction solutions. With over one million gear motors in service worldwide and with years of experience in the medical mobility market, ElectroCraft has been able to further innovate with higher performance and ever more robust motion solutions.

ElectroCraft gearmotors are renowned for their smooth, controlled power delivery, with high starting torque to provide excellent rough-terrain and curb-climbing performance. These characteristics make them ideal for rehab wheelchairs that can tilt, bariatric wheelchairs for patients weighing greater than 600 lb. and outdoor wheelchairs capable of handling uneven terrain.

ElectroCraft engineers are constantly developing new products, which has opened the door to new markets requiring motors and gearmotors with more demanding specifications. In addition to medical mobility, ElectroCraft mobile platform traction solutions are ideal for a wide variety of industrial, commercial and consumer product applications.

Some applications include automated guided vehicles (AGV), autonomous mobile robots (AMR) and motorized assist devices such as carts, tuggers and lift trucks that are used in automated warehouse and logistics operations. Other applications with demanding specifications that are ideal for ElectroCraft solutions are included in the rapidly growing field of mobile robotics. ElectroCraft products are found in surgical robots, industrial robots, agricultural robots, military robots, as well as professional and domestic service robots.

Custom Solutions

When an application requires specifications that are not available in a standard product, ElectroCraft specializes in developing customized solutions for the most demanding motion control requirements.

ElectroCraft engineers can also help identify the best gearing technology for the application by working with the customer to answer key questions.

- What are the physical limitations of the application?

- What orientation configuration is best, parallel, in-line or right-angle gearing?

- What is the reduction in speed or increase in torque ratio required?

- What are the drive train, system efficiency and overall battery life requirements?

- What is the sensitivity to noise?

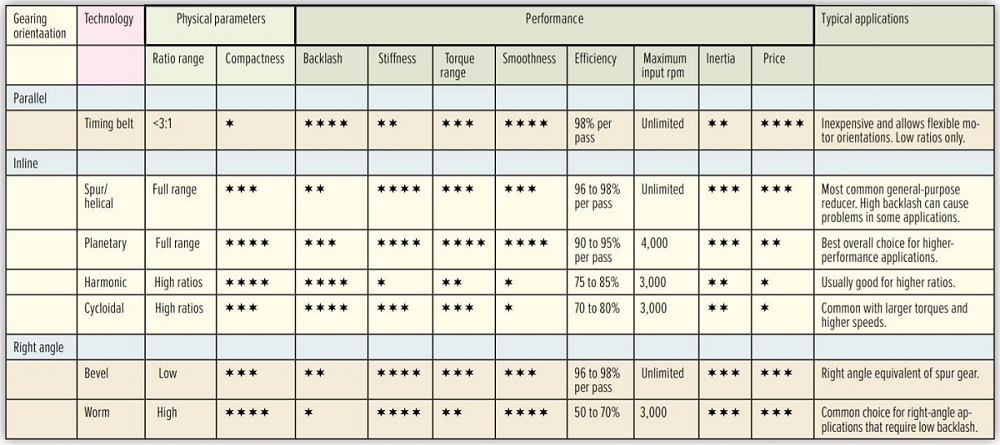

This will determine the reduction technology, which includes timing belt, spur or helical gear, planetary gear, harmonic drive, cycloidal gears, bevel gears, hypoid gears and worm gears.

The following chart provides an overview of various mechanical transmission options that can be incorporated in a custom solution.

With over 100,000 ft.² (300,000 ft.² in the U.S. and 100,000 ft.² in China) of manufacturing space, and dedicated North American and worldwide engineering team, ElectroCraft will design and build a motor that suits customer's mobile platform traction solution needs.

Conclusion

ElectroCraft brush and brushless DC motors and integrated gear motors are highly reliable, cost-effective, industrial-strength solutions. While they were originally developed for the medical market, they have evolved and expanded over time to become ideal mobile platform traction solutions for a wide variety of industrial, commercial and consumer product applications.

ElectroCraft engineers have the knowledge, experience and capability to develop highly customizable solutions for the most demanding applications when an off-the-shelf product is not available.

Contact a BLDC application engineer at sales@electrocraft.com for additional information.