Articles and Whitepapers

Whitepapers and application guides, articles and faqs on ElectroCraft motor and motion products.

This Design Guide provides engineers with a clear, comparative view of drive technologies—covering analog vs. digital systems, pulse-width modulation (PWM) vs. linear amplification, and centralized vs. distributed architectures.

Headquartered in the U.S., ElectroCraft is dedicated to U.S. manufacturing, and continues to invest in its state-of-the-art facilities in Gallipolis, Ohio, Princeton, Indiana, and Ann Arbor, Michigan. These locations are centers of excellence for precision engineering and the production of high-quality motion control solutions, supporting U.S. and global customers with American-made products.

Biomedical applications, such as pipetting and sample handling require the precise dispensing of fluids, on the order of micro-milliliters (or micro-mils), with margins of error lower than 5%. Equipment that fails to meet these stringent dispensing and accuracy requirements is simply unacceptable in the bio-medical market; this leads to erroneous results.

The ElectroCraft hybrid stepper motors, when combined with an integrated fine pitch lead screw or ball screw, this hybrid stepper linear actuator can provide micro-mil resolution with sub-micro-mil accuracy.

As automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) become more commonplace in warehouses and factories, design engineers are working on next generation platforms that can move faster and more efficiently while continuing to operate safely in collaboration with their human counterparts.

ElectroCraft offers a unique, integrated wheel drive platform, which provides increased performance and reliability at an affordable price compared to traditional motor/gearbox/wheel combinations (Figure 1).

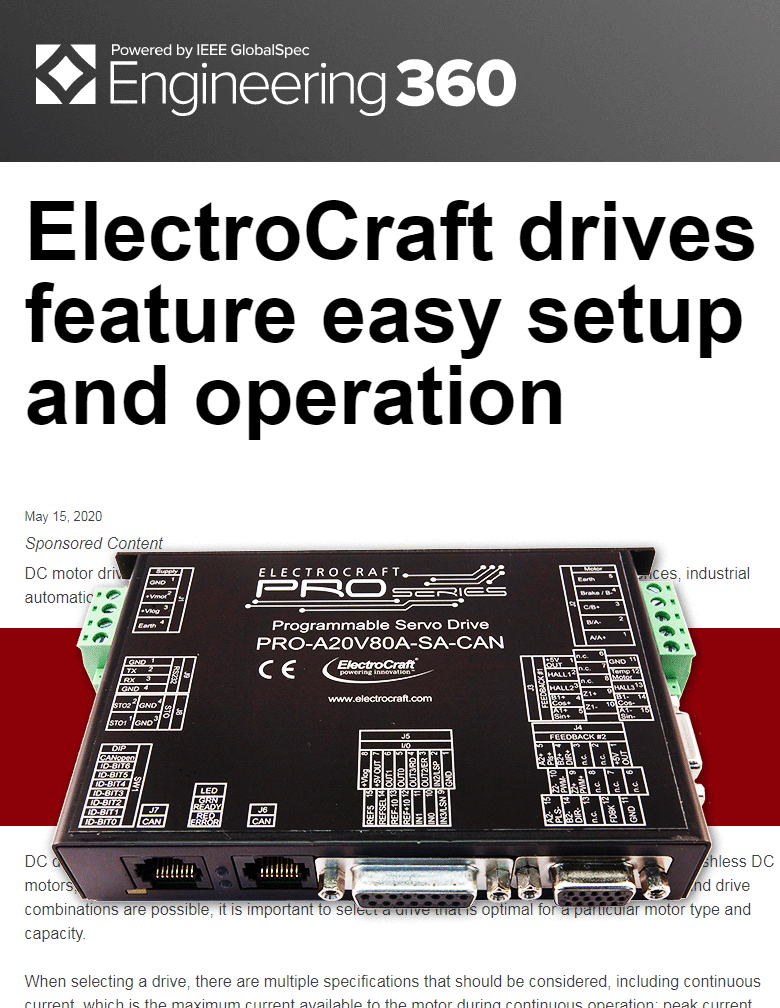

Among the challenges that design and control engineers must address are the pairing of motors with compatible drive electronics. Motors and drives must be properly matched and configured to ensure compatibility and optimal performance in regard to current, voltage, power and control requirements. Incompatibilities can lead to several problems such as motor overheating, excessive noise, inaccurate positioning, poor torque capability or fluctuating speed. Although these challenges can be daunting, there are solutions available to provide an affordable and easy-to-use platform that minimizes potential compatibility issues.

DC motors are motion components that take electrical power in the form of direct current (or some manipulated form of direct current) and convert it into mechanical rotation. Brushless DC motors do this through the use of magnetic fields that arise from the electric currents to spur rotation of a rotor fixed with an output shaft. Output torque and speed depends on the electrical input and motor design.

In this Design Guide, the editors of Design World detail the most common dc motor types as well common ways to quantify their output during the design engineering process.

ElectroCraft fractional horsepower (FHP) motor and motion control products are known for their durability, reliability and high performance, making them a top choice for customers in various industries. This article serves to better acquaint the reader with the ElectroCraft motor and servo drive product offer, this article will review: BLDC motor proliferation, the need for more sophisticated (but easy to use) servo motor drives, and the decision to buy versus make servo drive and motor control systems.

Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) are key elements in optimizing the efficiency and profitability of an automated warehouse. Minimizing the total cost of ownership (TCO) of the AGV or AMR is a must, and this depends heavily on the design of its drivetrain. If the OEM uses well-designed, proven components, the mobile platform will provide many years of service, handling cumbersome, heavy loads efficiently with minimal downtime for maintenance.

The ElectroCraft RapidPower Enhanced series (RPE series) is an innovative, new brushless DC (BLDC) motor design that combines performance, flexibility and affordability, offering original equipment manufacturers (OEMs) the perfect platform for a wide range of motion applications. This level of configurability for BLDCs enables the RPE series to be quickly acquired and adapted into an application, shortening the design cycle for a faster time-to-market.

ElectroCraft Continues to pioneer motor and drive solutions for medical and robotic mobility markets. The integrated mobility platform continues to evolve with custom mobility motor manufacturers developing the next generation of mobile power platforms that can tackle the mobility and industrial motion applications of today and tomorrow.

Stepper motors are commonly used to translate motion from rotary to linear. Selecting the right combination of electrical and mechanical components is complicated by the various options for precision positioning systems. This brief will review key criteria for successful stepper linear actuator specification and highlight the benefits of correct actuator and application pairings.

ElectroCraft's MobilePower™ MPW series integrated wheel drives benefit from the company's decades of mobile power design expertise. The product offers OEMs a compact, high-torque density electric wheel drive that solves drivetrain design challenges and cuts the lifetime running costs of mobile robots.

ElectroCraft CompletePower™ PRO Series Drives and CompletePower™ Plus Universal Drives take the guesswork out of selecting and configuring a drive and motor combination by incorporating all of the features and functions necessary to provide optimal control of a wide variety of brushless DC motors, permanent magnet DC motors and stepper motors.

In order to more efficiently utilize energy and reduce emissions in the oil & gas extraction process, our customer required an electric motor and drive solution for a glycol circulation pump that was currently being powered by a methane fueled combustion engine.

Torque density and speed requirements of a motion control system are often at odds with space constraints. In new system designs, the trend toward miniaturization continues to reduce size, weight and, ultimately, cost. This trend is also driving the need for highly efficient brushless DC (BLDC) motor solutions that can fulfill performance requirements in a much smaller frame size.

Learn how to make the best choice of motor or gearmotor for your application requirements. The factors in selecting the appropriate motor or gearmotor for your application may look simple at the outset but can get complex fairly quickly. By focusing on these six tips in order, engineers will find an easy path to their next motion control solution.

The evolution of DC motor and gear motor technology has opened the doors to lightweight, battery-efficient solutions for mobile platform traction systems. From medical mobility to industrial robotics and warehouse automation, mobile platform traction systems have become more affordable, manageable and efficient in large part due to the advancements of motors and integrated gearbox technology.

Technology advancements in motors, gearboxes, and battery life are expanding the design engineer's options when it comes to applications for mobile power platforms. Medical and industrial robotics, AGVs, all-terrain machines, and high-performance sports chairs are just some of the new markets that mobile power platforms are defining today, thanks to the wide range of integrated motor/gearbox combinations and recent technology advancements that provide powerfully responsive, efficient, and reliable operations. What new application area for mobile power platforms will your design team pioneer next?

“How Technology Advancements are Transforming the Mobility Market” is essential reading when considering a mobile power platform for your next application.

This updated handbook is a helpful guide outlining the design considerations, calculations and application of brushless servo sytems, including helpful engineering formulas and conversion tables.

Recently introduced designs, like those in ElectroCraft's LRPX series, combine specially-designed BLDCs with gearboxes for a streamlined gearmotor design. The integrated design minimizes the number of components for a smaller footprint, greater accuracy, and better dynamic response.

Read on to learn more about the difference between traditional BLDC motor options and integrated BLDC gearmotors.

Manufacturers apply the term "closed-loop stepper" to a wide array of controls. Here, we'll spell out how the three most common closed-loop stepper control schemes work and highlight their advantages and disadvantages.